Seats

We started to rebuild a borrowed jigg, like the way we want to make our seat. We decided to work with CF

so it is much more stiffer than the normal cloth and so we could work with the lighter foam (35kg).

The result is two seats and one backrest just below 3 kg.

With some heat we bend the foam into his curve, we used wire to hold it into position.

Put one layer CF on it. And after cure we removed the peel ply.

After we made a small correction on the jigg, we turned the seat on its other side. Then we glued a wooden

pine in position where the seat is bolted on the front spar. The lower side of the seat is made of 3 layers of

CF till the the hole of the stick.

Both seats in position. Trimmed in the right size.

To make the seat much more stiffer we made vertical flange on it.

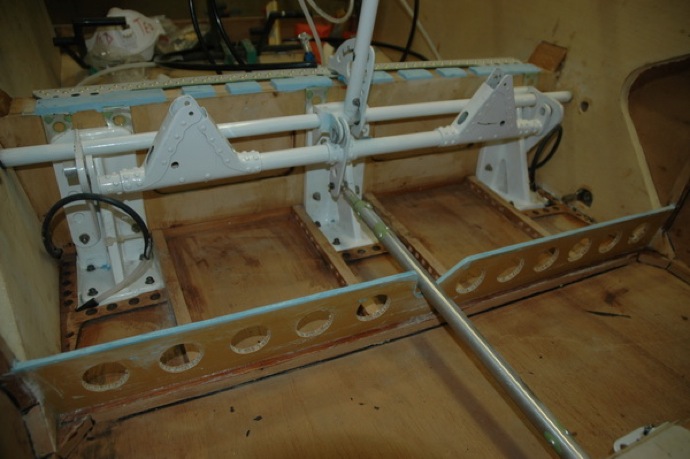

Nice view on the push pull bar and the clearance between the seat, now its the time to change the wooden

block for the final connection.

First we glued an aluminum tube in the right position, afterwards wrapped on layer of cf around it.

Temporary installed the seat on it’s brackets.

To tighten the center fueltank we made straps around the fwd spar so we didn’t have to drill in it. At the

straps we made attachment points for the seat.

We glued bushings into the wooden support (glued in the seat). The springs hold the bushings into position.

After the bushings are glued we can bolted the seat on the fwd spar.

Made an extra support, just for safety, because of the push pull bar. The seat bend without this support

and with 200 kg of weight 5 mm.

Made a notch on the lower side of the seat so the honeycomb support will stay in its position without screws.

Finaly both bolted into position.

My dad testing.

Back to home